Keep Ahead of Upkeep: Buying Top-Notch Komatsu Undercarriage Parts

Wiki Article

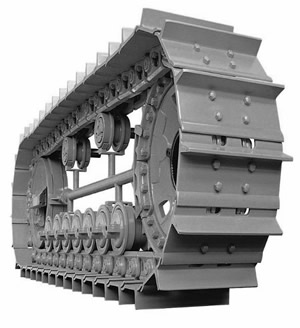

Reliable Solutions: Undercarriage Components for Heavy Machinery

When it comes to hefty machinery, the undercarriage is a critical part that often identifies the overall performance and performance of the devices. Quality undercarriage parts play a significant duty in making sure the smooth operation and long life of heavy equipment. From excavators to dozers, each tool counts heavily on its undercarriage to hold up against difficult working conditions. Wear and tear are unavoidable, leading to potential problems that can hinder performance and boost upkeep expenses. In this conversation, we will discover the importance of buying first-class undercarriage components, common wear obstacles faced by hefty machinery drivers, the advantages of timely substitutes, standards for picking trustworthy suppliers, and necessary upkeep suggestions to expand the lifespan of undercarriage elements.Relevance of Quality Undercarriage Parts

Quality undercarriage parts are important elements in making sure the longevity and efficiency of hefty machinery. The undercarriage of equipment such as excavators, excavators, and track loaders plays an important role in supporting the maker's weight, supplying security on different surfaces, and taking in the effect of unequal surfaces. By investing in top quality undercarriage parts, operators can significantly expand the life-span of their equipment and lower the danger of unforeseen malfunctions.One secret advantage of making use of top quality undercarriage components is the enhancement of overall machine efficiency. Sturdy tracks, rollers, sprockets, and idlers minimize friction and guarantee smoother movement, inevitably resulting in enhanced efficiency and efficiency on job websites. Furthermore, reputable undercarriage components minimize downtime for repair and maintenance, enabling operators to maximize their operational hours and project deadlines.

Common Undercarriage Use Issues

Advantages of Timely Replacement

One key benefit of prompt undercarriage component substitute is increased device uptime. By replacing used components before they fail, the risk of unforeseen malfunctions is lessened, decreasing downtime for repair work and upkeep. This aggressive technique not just maintains the heavy machinery functional however also prevents possible damages to various other elements that could arise from a stopping working undercarriage.

Additionally, changing straight from the source undercarriage parts promptly can boost overall efficiency. Spending in prompt undercarriage part replacement is an aggressive method that pays off in terms of improved effectiveness and lowered operational costs.

Selecting the Right Undercarriage Distributor

Selecting the appropriate undercarriage provider is a crucial decision that substantially influences the efficiency and maintenance of heavy machinery. When selecting a distributor for undercarriage components, several elements should be taken into consideration to ensure optimum effectiveness and cost-effectiveness. First of all, it is important to assess the supplier's credibility and experience in the market. A credible provider with years of experience is most likely to offer top notch components and reputable solution. In addition, think about the variety of items offered by the distributor. A distributor that provides a broad option of undercarriage parts for numerous hefty machinery brand names and models can be advantageous as it gives much more options to satisfy certain requirements.Moreover, examining the supplier's customer care and support is important. A vendor that uses exceptional customer support, fast action times, and technological aid can assist lessen downtime and make certain smooth procedures. Expense is likewise a substantial aspect to take into consideration; nevertheless, it ought to not be the sole factor. Balancing high quality, cost-effectiveness, and reliability is crucial when choosing the ideal undercarriage provider for hefty machinery. By meticulously evaluating these aspects, you can pick a distributor that meets your requirements and adds to the effective efficiency and upkeep of your hefty machinery.

Upkeep Tips for Extended Life Expectancy

To here are the findings make sure an extended life-span for hefty equipment undercarriage components, executing a proactive upkeep routine is important. Routinely evaluating undercarriage elements such as track chains, idlers, rollers, and sprockets for damage is essential. Any indications of damage or extreme wear must be quickly resolved to stop further degeneration and potential failings. Additionally, keeping the undercarriage clean from dust, debris, and harsh materials can substantially prolong its lifespan. Greasing moving components according to manufacturer suggestions helps in reducing rubbing and stop premature wear. Checking track tension and positioning is additionally important to stop uneven endure the undercarriage components. Investing in top quality undercarriage parts from reputable providers is similarly vital for guaranteeing long life. By following these upkeep suggestions carefully, hefty equipment owners can maximize the efficiency and sturdiness of click this site their undercarriage components, inevitably decreasing downtime and functional prices.Conclusion

In conclusion, top quality undercarriage parts are essential for the reliable operation of hefty machinery. Choosing a reliable distributor and complying with correct maintenance techniques are essential to ensuring the prolonged life expectancy of undercarriage elements.

Excessive wear and tear on undercarriage components of hefty machinery can lead to significant operational obstacles and boosted maintenance prices. Normal assessments, proper upkeep, and prompt replacements of worn undercarriage components are vital to mitigate these typical wear problems and ensure the optimum functioning of heavy equipment.

A provider that supplies a vast choice of undercarriage parts for numerous heavy equipment brands and models can be helpful as it offers a lot more alternatives to satisfy particular needs.

By complying with these maintenance pointers carefully, heavy equipment owners can enhance the performance and longevity of their undercarriage components, ultimately lowering downtime and operational prices.

Report this wiki page